My current monitoring on rev0.1 was a bit optimistic, so I’m complicating the isolated side by adding more opamps. Half an LM358 is used to sense the return current, the other half acts as V-I converter, driving a BJT through the optocoupler, here simulated with an LED.

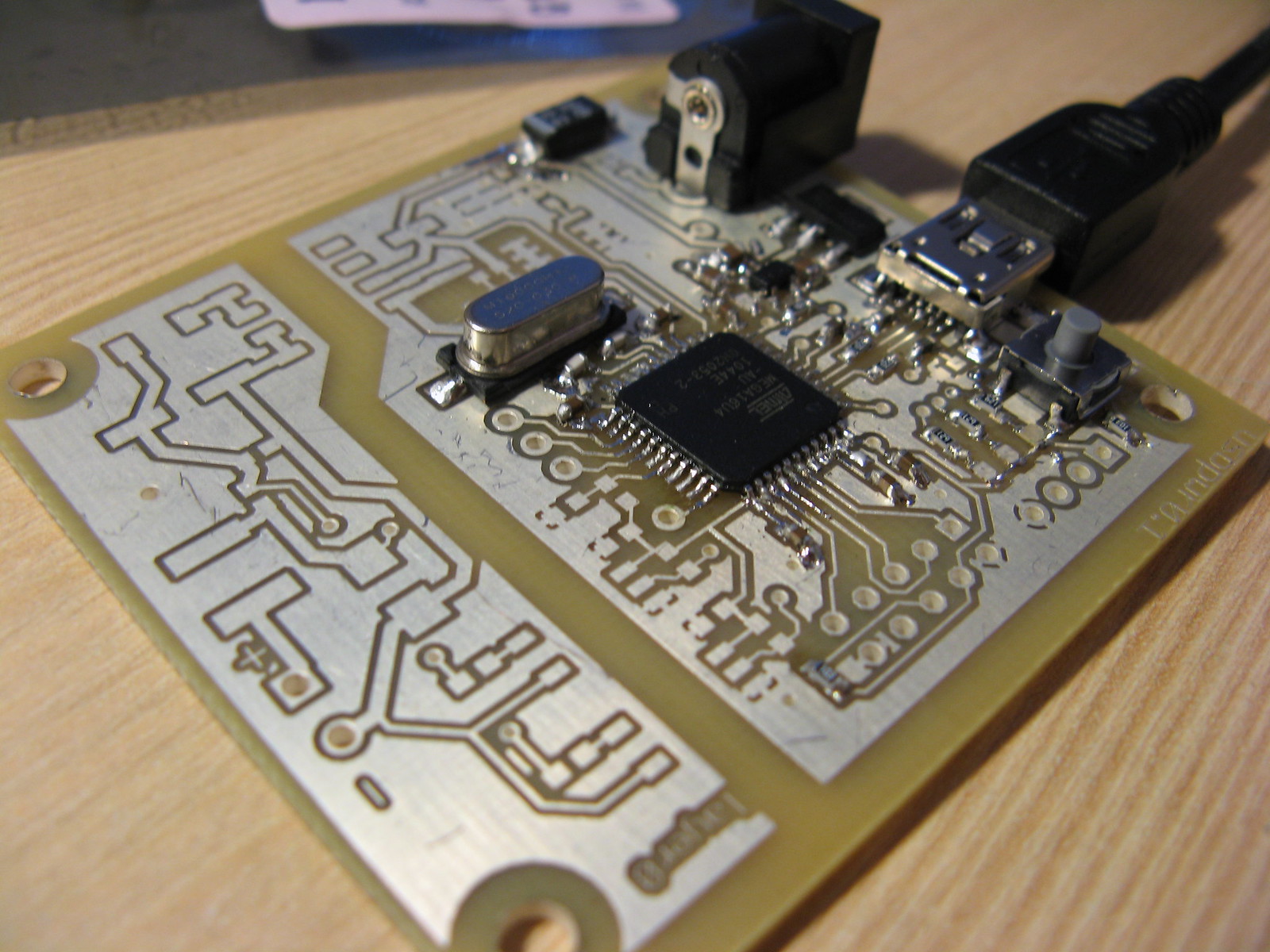

To test it, I need a variable voltage source – rev0.1 is already useful enough.

I have since simplified this design – LM358 can supply enough output current – no BJT is required.